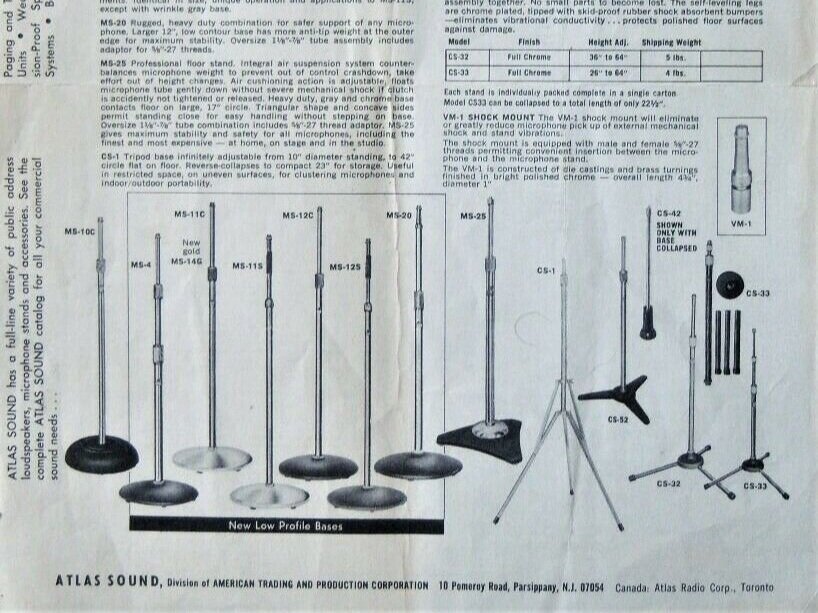

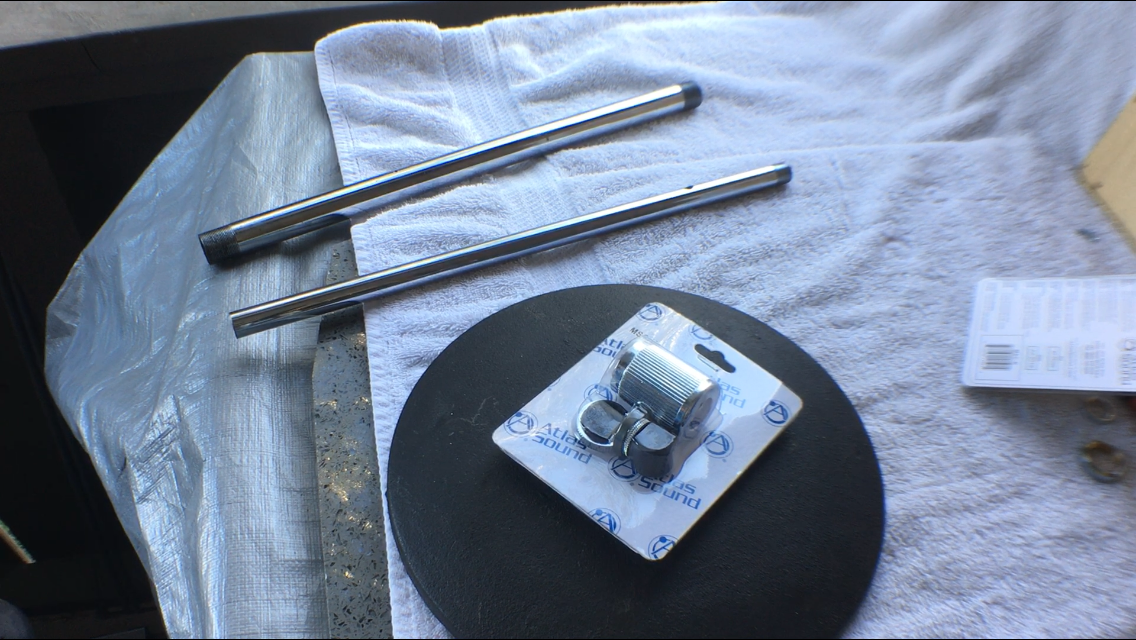

Mic stand shafts ready to be turned in to complete stands!

Here’s another #coronatimes project I’ve been working on which was a long time coming. Years ago, I saved some straight mic stand shafts which were missing their cast-iron bases from the garbage heap. I held on to them to build complete stands, and I’m finally getting it done.

2 HALF HEIGHT BOOM STANDS

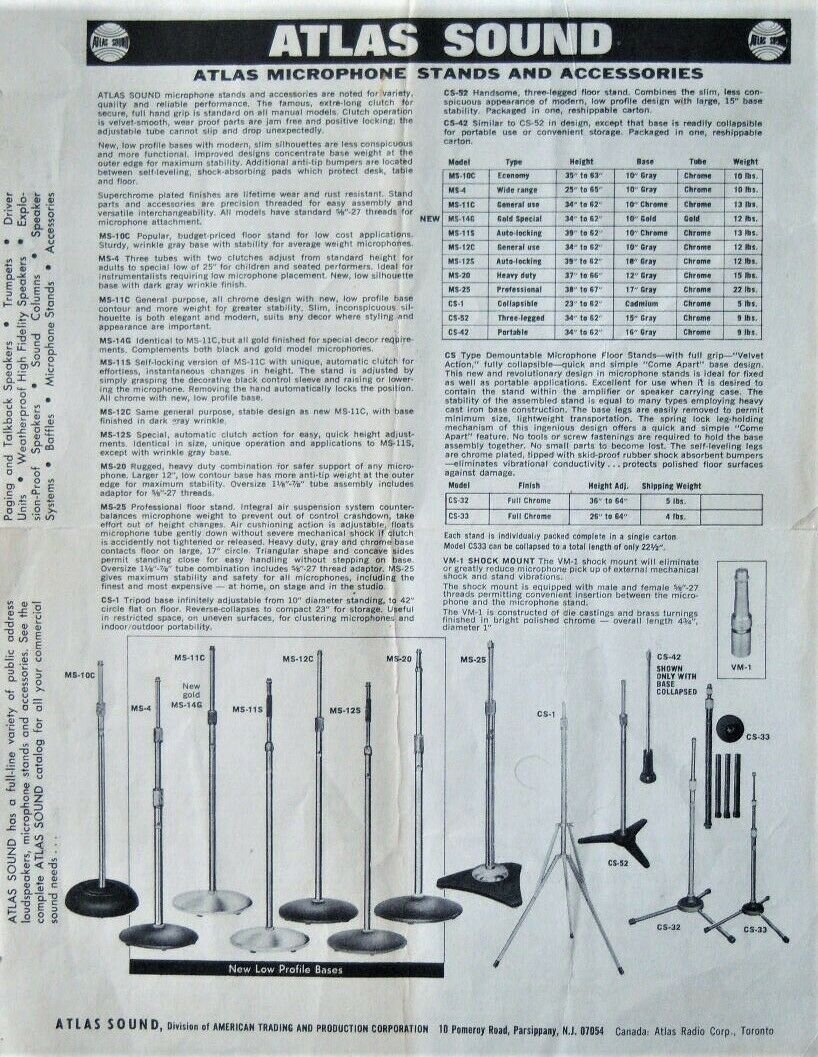

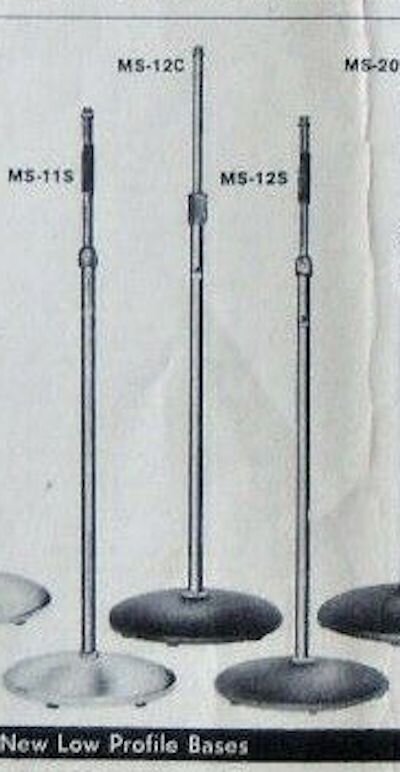

One of the stands I had was an MS-115/125. This is a straight, auto-locking stand, but the locking mechanism had (at least) two broken parts (a shaft and a collar), and because Atlas doesn’t make them any more, I don’t think I’d ever be able to find replacement parts without just buying another old stand. I also have a collection of mic stand booms without bases which I’ve collected from garbage cans and reconditioned over the years.

So I thought I just might be able to cut the stand in half, get new bases, for each, and put booms on top to make two half-height stands. I would like to have these anyway, for drums, guitar/bass cabinets, cellos/basses, or other low-ish instruments. In fact, I’d just moved my drumset with wood hoop toms in to the studio, so rim clamp mic brackets weren’t an option anymore, so I’d need mic stands to mic the toms. So that’s what I did.

I cut the stand in half, and threaded the ends. The end that goes in to the cast iron base is 7/8” diameter, 27tpi (threads per inch). The end which connects to the mic clip is 5/8”, 27tpi. 27tpi is kind of an oddball thread pitch, I learned, and I had to order the dies and die stocks on Amazon. I checked all local stores and rental places, but they mostly had tools for standard plumbing or electrical conduit. I also reached out to handymen and machinists on Craigslist, but they would all be much more expensive than just buying the needed tools and doing it myself. These will be good tools to have in the sound toolbox going forward, too to fix damaged or stripped threads. I used Balistol to lubricate and cool while machining the threads, dispensed from some small syringe bottles, also purchased on Amazon.

With the tubes cut and threaded, I purchased new cast iron bases, and clutch assembly kits on ebay, and put them together! They work great on my toms!

LINKS:

GROZ Professional Die Stock Holder | Suitable for 2-inch Round Dies | All Steel Construction (09114)

uxcell Die Stock Handle Wrench 45mm Diameter M16-M20 Metric Round Die Holder 175mm Handle Length

7/8" - 27 Unified Right Hand Thread Die

5/8" - 27 Right Hand Thread Die

6Pcs Syringe Bottle with 15Pcs Dispensing Needles and 12Pcs Cap (30ml+50ml)